====================================

====================================

====================================

BINTANG INSTRUMENT

HP : 081362449440 / 081310157965

Email : b081362449440@yahoo.com

Up : Mr Jonathan

====================================

====================================

| Smart Scan |

| Model : SMARTSCAN S50L |

| - Measuring Range : 0.4 to 12m |

| - Accuracy : 0.2% Of The Measuring Range |

| - Enclosure : IP65/ NEMA4, Panel / Wall Mounting |

| - Operating Temperature : -20 C to 60C |

| - Display : Costumized LCD |

| - Supply {Power : 100-240 VAC, 50HZ , 70 MA |

| - Max Out Put : 4-20 MA , 24 VDC |

| - Interface : RS-232 Or RS-485 PN : S50-LB51-6G8AC |

| SENSOR : |

| - P/N : SN5X1AAC |

| - Manufacture : SOLID |

| - SENSOR : <(>&<)> Cable |

| - Wetted Parts : Polyprop ( PP ), Glass Reinforce Epoxy |

| - Operating Pressure : Atmospheric |

| - Operating Temperature : -20C to 100C Y53 |

| - Signal Power Between Unit &Sensor; :Min. 4VP -P , |

| Max .400VP-P |

| - Mounting : 1" BSP, 1"NPT |

| - Transducer : 50 KHZ |

| - Max Sensor Cable to Unit Distance : 200m |

===============================

===================================

==========================================

FCX-AII Level TRANSMITTERS

Direct Mounted Flange Type

High performance level measurement using a differential pressure transmitter.

|

|

Most DP type level transmitters use an 'O' ring seal which will perish within 6 to 12 months usage in a hostile process environment. The FCX series transmitter uses an all-welded construction with fill fluid that has been subjected to high vacuum for an extended period to remove entrained air. This provides long term reliability not found in any level transmitter of it's type.

=========================

==============================

=====================================

Ultrasonic Level Transmitters

(You need more information on Ultrasonic Level Measurement?)

|

MonoScan |

|

|

More flexibility, more compatibilityUltrasonic Level transmitter MonoScan® is an excellent choice for measuring liquid and solid levels at ranges of up to 15 meters, with a 0.25% accuracy of measuring range. The MonoScan® single enclosure and compact sensor, ensures a full match with your installations. Moreover, the MonoScan is the smallest ultrasonic gauging device for measuring open channel flow, incorporating 9 predefined types of weirs and flumes in its memory that assures fast and easy set- up.

Ultrasonic Level Transmitter Advantages

Applications

|

==========================================

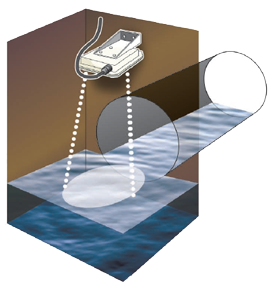

Non Contact 2 Part Ultrasonic Level Transmitter

SmartLite is a non contact, ultrasonic, continuous level measurement instrument that is able to provide accurate measurements for liquids while automatically compensating for changes in temperature and other environmental conditions.

Smartlite Level Transmitter

SmartLite is designed for applications such as process tanks, storage vessels, open air piles, and more. SmartLite is a four wire, low voltage device, and is available with a customized graphic LCD display.

SmartLite has two major components, the main control unit and the sensor.

Features:

- Installation in process tanks, storage vessels, open air piles and more.

- Self-adjustment to virtually all types of conditions

- Full compensation in virtually all environments: vapors, gases, temperature variations, wind, etc. providing highest accuracy even under extremely harsh conditions

- 0.25% accuracy of measuring range

- For ranges of up to 10 meters (32 ft)

- Resolution: 1 mm (0.04 inch)

- No calibration or maintenance required

=========================================

Ultrasonic Level Transmitter - Gauger GSM

Level sensor with integrated GSM modem

Gauger GSM Level Transmitter is targeted towards specific niche markets:

Remote fuel tank management including fuel theft detection long life in-ditch waste-water monitoring and early warning flood alert systems.

The GaugerGSM is certified to Ex II 1G, Ex ia IIB T4 Ga with Ta = -30°C to +70°C and defined as intrinsically safe. The system is allowed for use in all zones: 0, 1 and 2. The system has been certified to both ATEX and IECEx by SIRA a leading UK Ex certification body.

Solid AT Gauger GSM Level Transmitter

Benefits:

- Complete data ownership ‐ no on‐going fees for control software

- Rapid return on investment - measured in months

- Fit for any site where SMS or GPRS is available

- Flexibility for customized alerts and reports

- 24/7 monitoring

- certified to Ex II 1G, Ex ia IIB T4 Ga with Ta = -30°C to +70°C and defined as intrinsically safe

- Complete set of parts available

Typical Applications:

- Fuel tank monitoring

- Detecting fuel theft and leakage

- Continuous inventory tracking

- Wastewater monitoring

- Detecting sewer blockage and overflow

- Wastewater spill recording

- Simple installation - no road digging

- Water reservoirs and rivers

- Detecting flood conditions

- Periodic and on‐demand reports

==========================

===============================

MRG-10 Level Transmitter

| The radar pulse is virtually unaffected by the contents and

atmosphere of the tank, temperature or pressure. Thus radar measurement

is proven to be the most reliable gauging method in most applications. Furthermore, maintenance requirements are practically zero because no part of the gauge is in physical contact with the liquid. These features make the MRG-10 guided wave radar very well suited for storage and buffer tanks in the chemical and water industry. |

|

The MRG-10 is most appropriate for calm liquid surfaces. If you

intend to use the MRG-10 to measure turbulent surface liquids, it may be

recommended to employ a still pipe used in order to achieve a calm

surface

The MRG-10 is appropriate for storage tanks or buffer tanks that have relatively calm surfaces.

- Chemical and petroleum

- Pharmaceuticals

- Food and beverage

Other applications include:

- Industrial water such as river intake gates

- Water supply

- Sewage water treatment plant

- Hydraulic power station

==============================

Tokyo Keiki MRF-10 Flat Radar Level Sensor

Features:

|

|

| Typical Application

Construction:

|

.

.

.

..

.

.

.

.

Tidak ada komentar:

Posting Komentar